Oil-filled bushing, transformer and other oil-deficient equipment are one of the main equipment in power system, which plays an important role in power system, and its reliability directly affects the operation safety of transformer and power grid. Due to the particularity of the oil-taking structure of oil-deficient equipment, there are few effective live detection or online monitoring methods for oil-filled bushing and other oil-deficient equipment at present. If a simple and effective on-line monitoring method can be adopted to find the defects in time before the failure of oil-filled bushing and take effective measures, the occurrence of major accidents will be avoided.

The hydrogen is the main characteristic gas in the internal discharge (partial discharge, spark and arc) of oil-filled electrical equipment. Hydrogen detection is also an early fault monitoring method of oil-filled electrical equipment recognized by IEEE(IEEEC57.104-1991), which has been widely used to monitor early faults of oil-filled electrical equipment. Therefore, by installing an on-line detection device for hydrogen in oil at the oil intake valve of oil-filled bushing and other oil-deficient equipment, the hydrogen concentration in oil of oil-deficient equipment can be monitored in real time and on-line, and when the concentration and change rate of dissolved hydrogen in oil exceed a certain limit, an alarm signal can be sent out, and effective measures can be taken in time to reduce or avoid the occurrence of oil-filled equipment failures.

In addition, oil and paper will decompose to produce gas when the oil-deficient equipment has internal discharge or thermal failure. When the gas exceeds the solubility of oil, the fault gas will gather at the oil storage cabinet at the top of the casing, which will increase the internal pressure of the casing. Therefore, the real-time monitoring of the internal pressure of the casing is realized by installing a pressure sensor at the oil intake valve of the oil-deficient equipment. When the internal pressure of oil-deficient equipment such as casing exceeds a certain limit, an alarm signal will be sent out, and effective measures will be taken in time to avoid the occurrence of equipment failures.

Excessive micro-water content in oil will accelerate the aging of insulating materials and reduce their dielectric strength. In extreme cases, this may lead to arcing and short circuit between windings. Therefore, it is very important to continuously monitor the content and change rate of micro-water in the oil of oil-deficient equipment for continuously evaluating the insulation characteristics of oil-deficient equipment such as casing.

Considering that the structural strength of the casing oil-taking valve body is small, the installation space is narrow, and there is a certain intensity of vibration during the operation of the casing, there is a risk of oil leakage and oil leakage at the connection of the oil-taking valve port when installing the online monitoring device. In addition, the installation of separate hydrogen sensors, pressure sensors and micro-water sensors through the three-way (T) or four-way (+) connection not only leads to the decrease of detection accuracy and response rate of hydrogen and micro-water due to the existence of "Bypassed Area", moreover, the increase of adapter also increases the hidden danger points of oil leakage and oil leakage.

Therefore, there is an urgent need for an on-line device with small volume and light weight, which can realize the integrated monitoring of four parameters such as hydrogen in oil, oil pressure, micro-water in oil and oil temperature.

With the support of State Grid Shaanxi Electric Power Company, H2SENSE adopts thin-film sensor technology with completely independent knowledge products. Through the mature MEMS technology, the chip-level integration of multi-parameter measurement is realized, and a multi-parameter on-line monitoring device (four-parameter integration) suitable for hydrogen, oil pressure, micro-water in oil and oil temperature in oil-deficient equipment is developed. The product is small in size and light in weight (300g, without adapter), and can be directly installed at the oil intake valve of oil-deficient equipment. It can realize on-line monitoring of hydrogen, oil pressure and micro-water in oil, fill the domestic blank, and can replace American imported products.

Hydrogen sensor based on palladium alloy thin-film technology is used to detect dissolved hydrogen in oil, which can directly put the sensor chip in transformer oil without oil-gas separation device and moving parts, and simplifies the sensor structure. It greatly reduces the maintenance cost and prolongs the service life of the hydrogen sensor. The mature and reliable thin-film pressure sensor is used for oil pressure measurement, which has the characteristics of high detection accuracy and wide range, and is suitable for measuring the pressure of mineral oil medium. Micro-water in oil is detected by polyimide thin-film capacitive humidity sensor.

In 2021, the four-in-one sensor has passed the type test of the Electrical Equipment Quality Inspection and Testing Center of the electric power industry, and the test results are qualified, and the tested items meet the requirements of DL/T 1432.1-2015 and other standards.

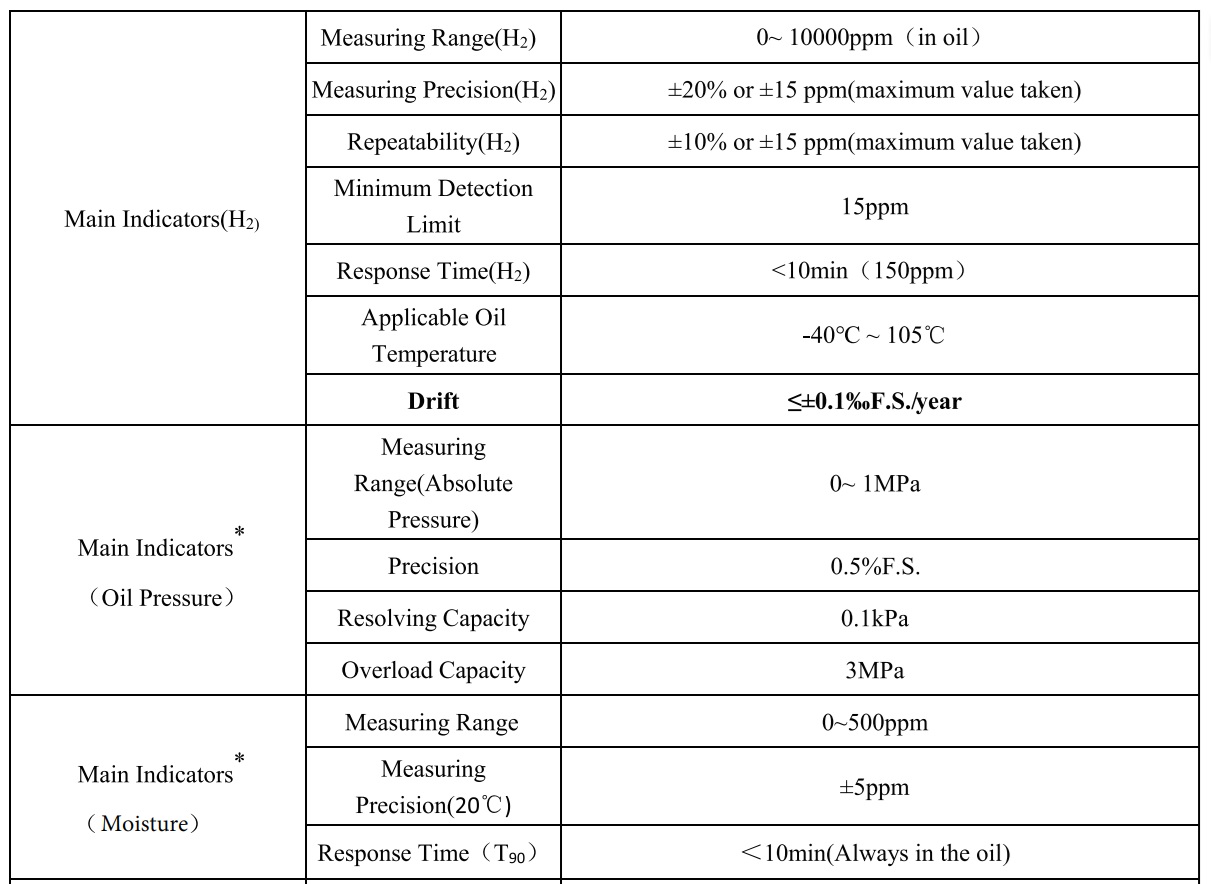

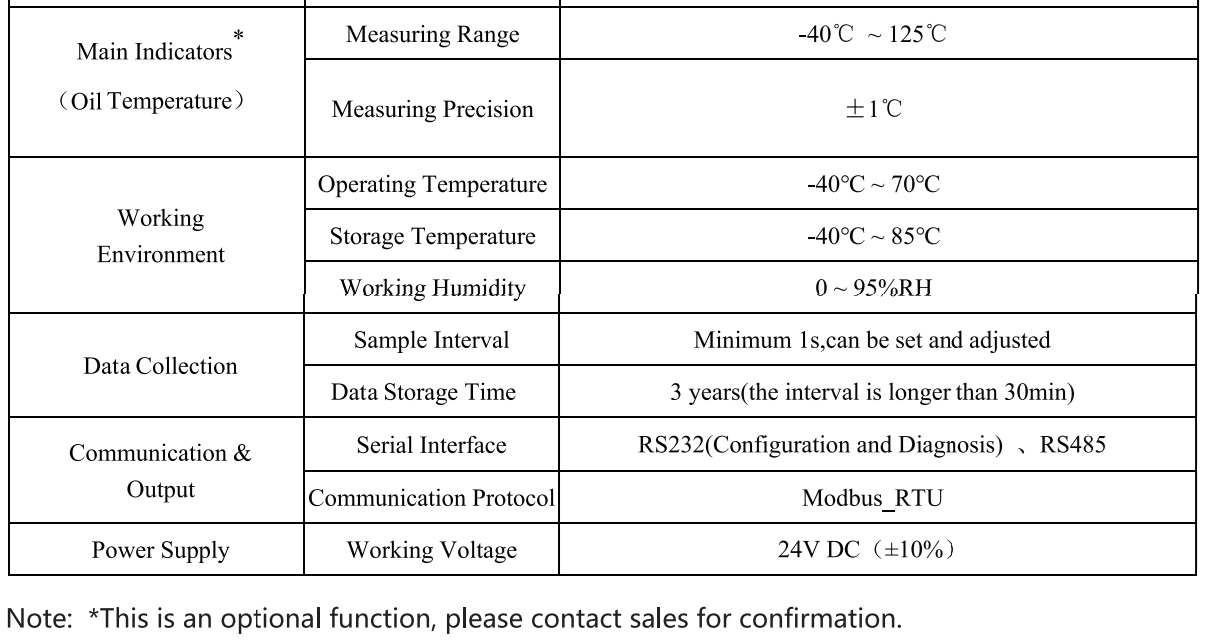

Main technical parameters of four-in-one hydrogen sensor