Demonstration Project of Intelligent Safety Wind Tower at the Wind Farm of China General Nuclear Power Group

On June 15, 2019, Hydrogen Sense Technology Co., Ltd completed the acceptance of the hydrogen concentration monitor in transformer oil in the smart and safe wind tower demonstration project of the Qiujialun Wind Farm of China General Nuclear Power Group. The safety status of the two running wind turbine transformers is being presented to the wind farm control center and the company headquarters leaders in the city through 4G wireless transmission.

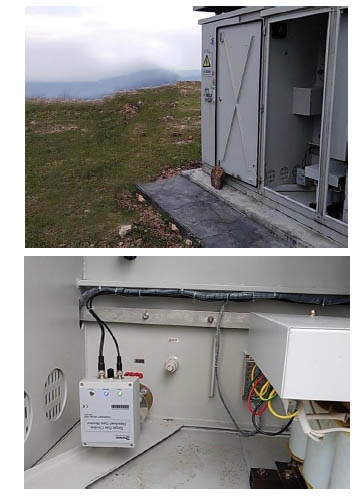

The H2SENSE company has a professional sensor design and installation team, relying on mature overall solutions and rich engineering case experience, and adopting MODEL3000 series online hydrogen monitoring device and 4G wireless transmission module and software independently developed by the company according to the actual situation of wind farm and customer demand. It completes the on-line remote monitoring of dissolved hydrogen concentration and oil temperature in the oil of wind tower transformer, and the operation effect of the sensor has been highly evaluated by the owner.

China General Nuclear Power Group Qiujialun Wind Farm has a total investment of 458 million yuan and an installed capacity of 50 MW. There are 25 wind turbines in the first phase of construction of Qiujialun Wind Farm. Each wind turbine consists of three blades with a length of 59.5 meters, a hub and a tower with a height of 90 meters. The first-phase wind farm was connected to the grid at the end of 2017, and the annual on-grid electricity consumption exceeded 100 million kWh.

As an important part of wind farm, transformer failure not only affects the power generation of wind farm, but also causes serious transformer explosion accidents, which even leads to mountain fires and greater economic losses. As the first safety monitoring instrument for wind power transformers in China, MODEL3000 series online monitoring devices for dissolved hydrogen in oil can remotely monitor and manage the dissolved hydrogen concentration, oil temperature and micro-water content of oil-filled transformers in real time. Through the collected real-time parameter values and daily change rate data, the running state of the transformer can be forewarned, and the transformer can be checked or stopped in time before it breaks down, which is especially meaningful for transformer safety monitoring in remote mountainous areas and shallow sea areas.