New Underwater Hydrogen Sensor Unveiled: High-Precision Real-Time Monitoring for Industrial Safety

Recently, the research team at Hydrogen Sense Technology Co., Ltd. successfully developed a new type of underwater dissolved hydrogen sensor and its manufacturing method, overcoming the technical challenges of traditional hydrogen sensors being prone to damage and unable to operate stably for long periods in weakly conductive media. This underwater hydrogen sensor boasts advantages such as a simple structure, high sensitivity, and ultra-low power consumption, making it suitable for a wide range of industrial applications, including power, petrochemical, and semiconductor industries, providing a reliable solution for real-time monitoring of dissolved hydrogen in water.

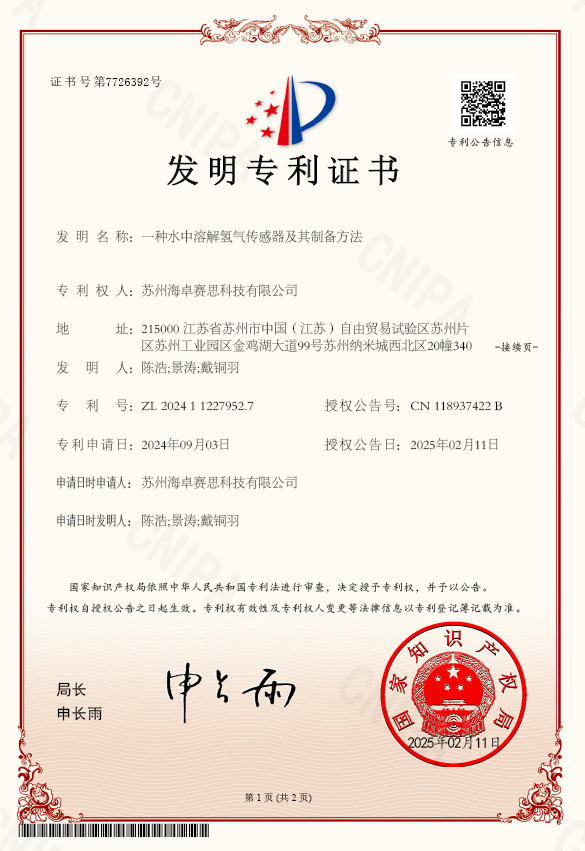

Patent for Invention: An underwater Dissolved Hydrogen Sensor and Its Preparation Method

Technological Innovation: Super-hydrophobic Coating + Wheatstone Bridge Structure

The core design of underwater hydrogen sensor features the following highlights:

1. Polyimide (PI) Flexible Substrate and Dual Hydrogen-Sensitive Chip Design:

l Flip-chip bonding technology is used for electrical integration, ensuring high precision and stability.

l Two hydrogen-sensitive chips form a Wheatstone bridge structure:

One chip is exposed to water, the other chip is sealed in a closed chamber for environmental compensation, significantly improving measurement accuracy.

2. Super-hydrophobic Coating Technology:

l A composite coating of nano-alumina particles and graphene is applied to the sensor surface:

Nano-Alumina: Provides mechanical support and insulation.

Graphene: Leverages its super-hydrophobic properties to effectively isolate water while allowing hydrogen molecules to pass through freely, ensuring the underwater hydrogen sensor can work reliably in extreme environment. Lab data shows that the underwater hydrogen sensor can continuously monitor the concentration of dissolved hydrogen in water (2ppm~20000ppm) with excellent repeatability and stability.

Breaking Industry Pain Points: No Heating Required, Low Power Consumption, Real-Time Monitoring

Traditional hydrogen sensors rely on heating elements to maintain operating temperature, which not only consumes high power but also tends to fail in weakly conductive media due to current leakage. This new product eliminates the need for heating and temperature measurement components through its Wheatstone bridge design, with an operating current as low as 1 mA, significantly reducing power consumption and making it suitable for long-term underwater deployment. Additionally, flip-chip bonding technology and sealant encapsulation effectively prevent short-circuit risks caused by exposed metal parts, ensuring reliability in complex working conditions.

Broad Application Prospects, Driving Industrial Intelligent Upgrades

The underwater hydrogen sensor can monitor dissolved hydrogen concentration in media such as generator cooling water and transformer oil in real time, preventing safety hazards such as equipment aging, short circuits, and even explosions caused by hydrogen accumulation. Currently, the industry relies heavily on offline laboratory testing, which is time-consuming and unable to provide dynamic data tracking. The advent of this product will drive the industry's transition from "periodic sampling" to "real-time monitoring," supporting the intelligent and safety-focused upgrades of critical areas such as power systems and petrochemical facilities.

The research team stated that this technology has entered the industrialization phase, with future efforts focused on optimizing the coating process and expanding the sensor's applications in emerging fields such as marine exploration and hydrogen energy. With the rapid development of the global hydrogen energy industry, this innovative achievement is expected to become a key technological pillar for ensuring industrial safety and efficient operations.